1. Weak cores are reinforced using what?

a) Iron wires

b) Steel wires

c) Bronze wires

d) Cobalt wires

Explanation: Weak cores need to be strengthened. And hence, for this purpose, reinforcement is provided, in the form of steel wires.

2. In shell core making, the core box is heated up to what temperature?

a) 400°F – 600°F

b) 500°F – 700°F

c) 600°F – 800°F

d) 800°F – 1000°F

Explanation: A decent amount of temperature has to be attained for the operation of shell core making. In shell core making, the core box has to be heated to a temperature of almost 400°F – 600°F.

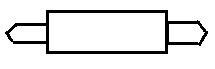

3. What does the following figure represent?

a) Sand slinger

b) Core extrusion machine

c) Pattern and core prints

d) Core blowing machine

Explanation: The following figure represents pattern and core prints. These core prints make up core seats when they are put into the sand for making mold.

4. A sand slinger works at a high speed.

a) True

b) False

Explanation: A sand slinger uses a high speed rotating impeller which is used for throwing sand in the core box.

5. Cylindrical cores are made using Dump core boxes.

a) True

b) False

Explanation: Dump core boxes are helpful in making rectangular or square cores. Cylindrical cores are made using half core boxes.

6. Which of the following equipment is used for both limited and mass production?

a) Core ovens

b) Dielectric bakers

c) Radiant bakers

d) Flame bakers

Explanation: Core ovens are the equipment which can be used for the making of limited productions. It is also a good choice if the production is going to be a mass one.

7. After preparation of cores, cores on the core plates are sent for what?

a) Pressurizing

b) Baking

c) Increasing the volume

d) Decreasing the volume

Explanation: Baking is a process that takes place after quite a lot of preliminary operations. After the cores are prepared, the cores are then placed on the plates and moved forward for baking.

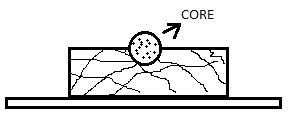

8. What does the following figure represent?

a) Core plate

b) Core drier

c) Core oxidizer

d) Core rack

Explanation: The given figure is a core drier. It is a wooden piece which is having a semi circular groove used for supporting a round core.

9. Cores are baked up to what temperature?

a) 600°F

b) 650°F

c) 700°F

d) 750°F

Explanation: Before the beginning of the process, the cores need to be taken to a decently good amount of temperature by preheating them. While baking the cores, the cores are taken up to a temperature as high as 650°F.

10. The moisture of the core is taken off during baking at what temperature?

a) 197°F

b) 212°F

c) 278°F

d) 304°F

Explanation: 212°F